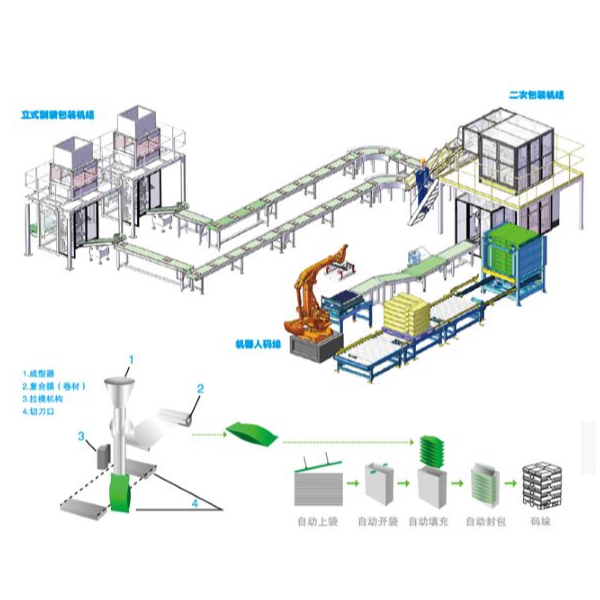

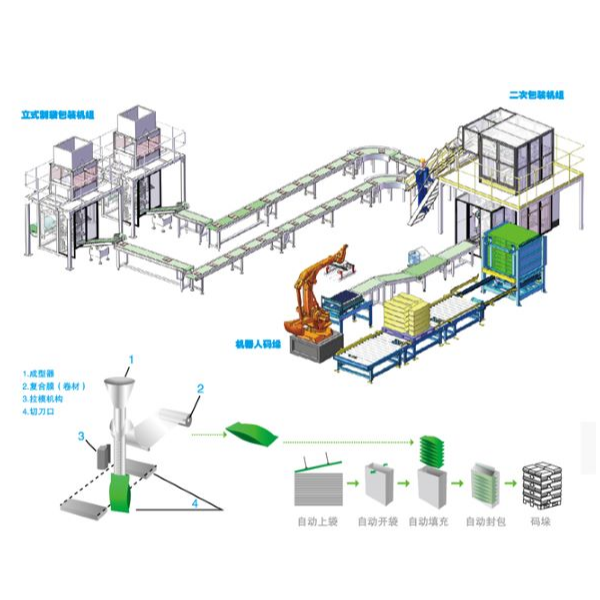

Equipment introduction:

This unit is mainly to complete the automatic packaging process of neatly filling the packaged small bags (150-1000 grams) into woven bags according to requirements (arrangement form: single warehouse or double warehouse, single row or double row), and sewing the bag for output. This realizes the fully automated operation from small bulk material packaging to woven bag packaging, saving manpower, material and financial investment, reducing production costs for customers, and improving production efficiency. It is the first choice for major companies to achieve full automation of post packaging machine.

Equipment composition:

Weighing machine→vertical bag making and packaging machine→over conveyor→horizontal conveyor→double-layer inclined conveyor→high-speed conveyor→counting and packing machine→woven bag automatic packaging machine→sewing machine→woven bag product output.

Production Process:

Small bag products → horizontal conveyor → double-layer inclined conveyor → high-speed conveyor → counting and packing machine → woven bag automatic packaging machine → sewing machine → woven bag product output.

Palletizing line for secondary packaging production